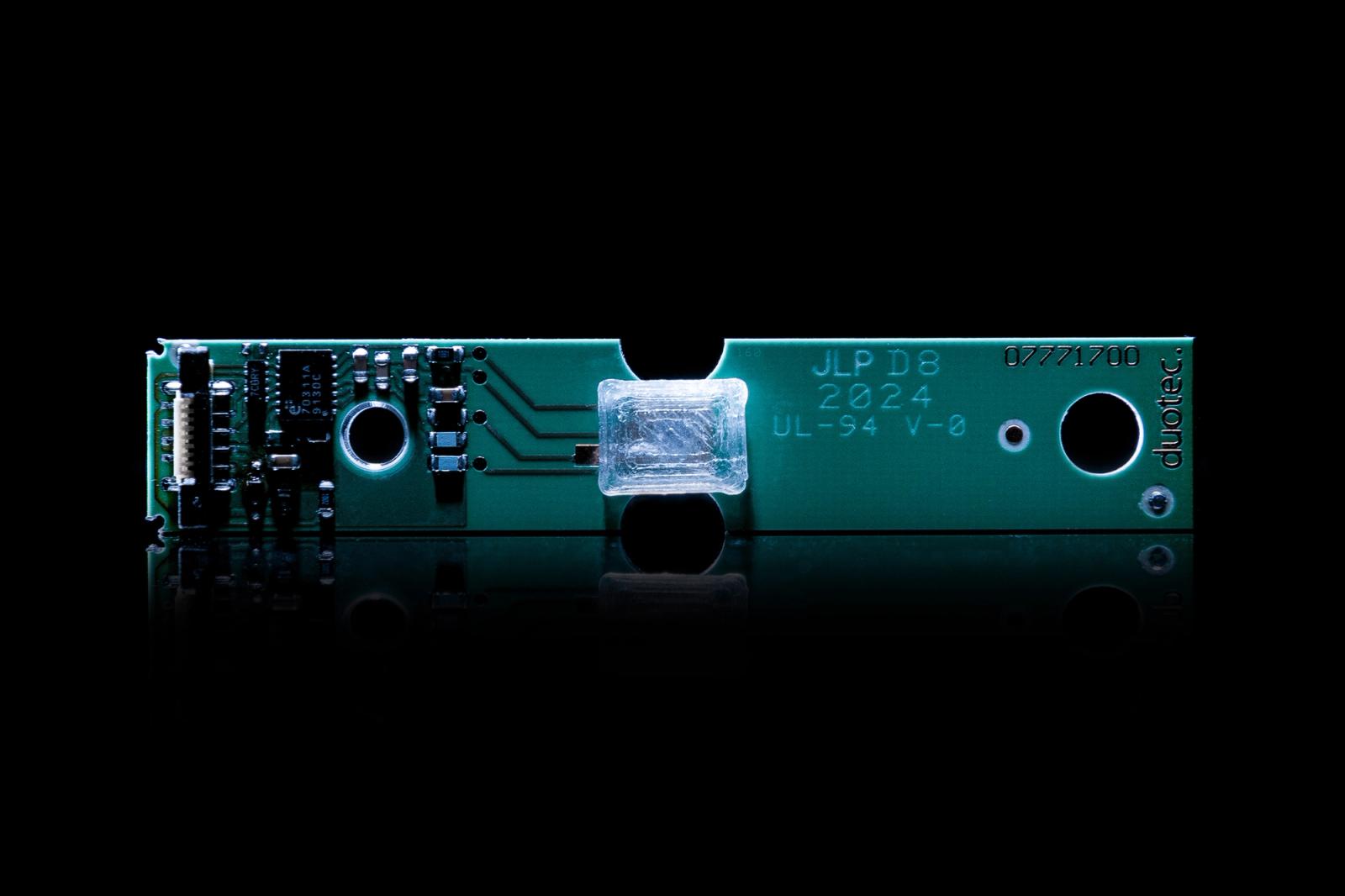

Force Sensor Silicon Strain Gauge (Si-SG)

Efficiency for demanding applications

How does the duotec force sensor change the accuracy of force and strain measurements?

Our Force Sensor sets a new standard for measuring force and strain, even when minimal changes are made. Conventional strain gauges (Si-SGs) often reach their limits when the strain is too small. Or they require complicated manual assembly. Furthermore, commercially available strain gauges are often inefficient due to high power consumption and heat generation in the low-impedance bridge and are unsuitable for stand-alone or battery-powered devices.

Our Silicon Strain Gauge (Si-SG) overcomes all of these challenges with an innovative technology that enables it to be used in industrially automated applications and offers a sensitivity that is up to 40 times higher than that of conventional strain gauges.

The special Si-SG technology enables industrial assembly automation and very low power consumption through a high-resistance 5k ohm measuring bridge. The sensor's capabilities include strain detection, an integrated temperature sensor, and customizable evaluation electronics, rendering it well-suited for a broad spectrum of applications. The adjustable sample rate and cut-off frequency make it very flexible. It can be directly mounted on sheet steel without evaluation electronics, which makes it easy to use in existing customer systems. This sensor is a universal tool for the most demanding industrial requirements.

Key Facts

- High Sensitivity: Up to 40 times more sensitive than conventional sensors – perfect for detecting the smallest strains.

- Miniaturized: Designed for measurements in confined spaces or precisely at the relevant point.

- Energy Efficiency: Low power consumption thanks to a high-resistance 5k-ohm measuring bridge with minimal power loss.

- Thermal Stability: Accurate results even under changing thermal conditions thanks to its smart evaluation electronics.

- Robustness: Suitable for extreme environments and industrial applications.

- Flexibility: The adjustable sample rate, cutoff frequency, and type of output signal ensure maximum flexibility in data acquisition.

- Industrial Automation: Efficient production processes thanks to easy application and integration into existing production systems.

Application examples:

Medical Technology

High-precision force measurement in surgical instruments.

Industrial Automation

Real-time monitoring of process forces to optimize manufacturing workflows.

Robotics

Precise force control in cobots for safe human-robot interaction.

Download the handout now and learn more!

These innovative SI-DMS-based force sensors offer a flexible and highly precise solution that seamlessly integrates with your specific requirements.

Request more information or a personalized quote today:

We use cookies and anonymized tracking to improve your experience. Datenschutz